About Us

NEEL INDUSTRIES

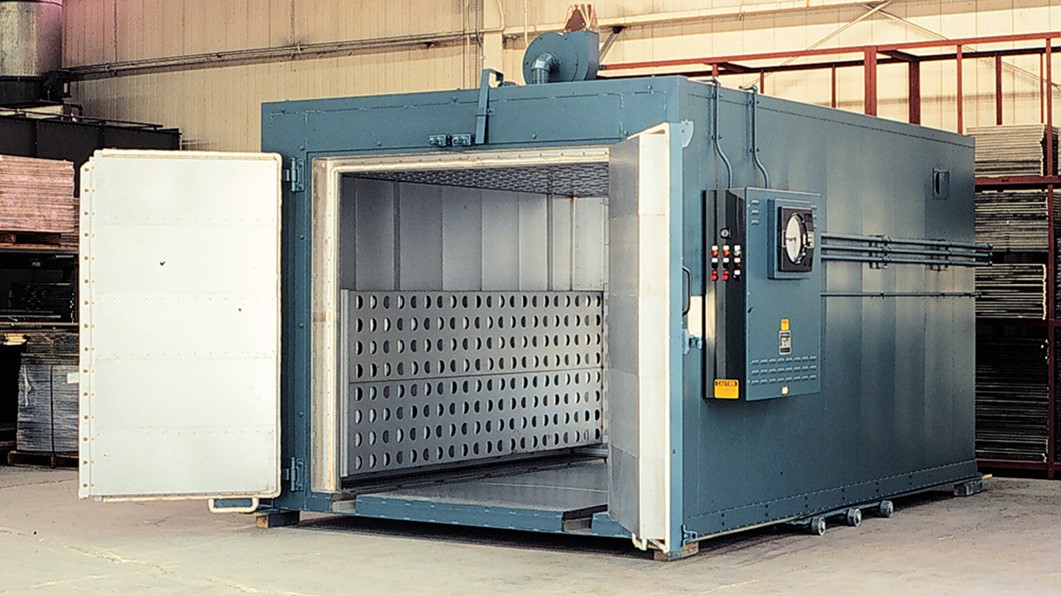

Industrial Ovens Manufacturers

Quality Comes First! We Make Sure That Every Minute Detail Is Looked Into While Manufacturing Even The Smallest Product. Our Focus Is 100% On Client Needs And Satisfaction.

Industrial ovens are thermal processing machines that provide various applications with the very important process of heat treatment. During this process, heat speeds up the molecular activity inside an object. Inside solid objects, molecules are arranged in lattices that vibrate from the heat, while in gases, these molecules collide. This activity changes the properties of the object it is heating, and strengthens it.

Our Work

Numbers Speak For Themselves

Applications

Industrial ovens have a wide range of applications in countless industries, such as: manufacturing, electronics, food and beverage, medicine and healthcare, pharmaceuticals, chemical, research and development, plastics, aerospace, automotive and metal forming.

Industrial ovens help make stronger metal products, more sanitary healthcare facilities and more versatile extruded polymer products. They are also used to treat products like steel coils, automotive parts, tubing, electronics, building materials, fuel cells, carpeting and textiles. In addition, laboratories use them to learn more about and refine industrial heat transference (laboratory oven). Such research leads to the reduction and elimination of heat transfer inefficiencies and the introduction of new heat treat applications.

Specifically, they’re used to carry out processes including: sintering, curing and powder coating. Note: Sintering is the process by which large particles are created out a pile of small, fine particles via the application of heat below the melting point. The goal of curing is to solidify a material by heating and drying it at a constant temperature.

How It Works

Industrial ovens work using heat and mass transfer, which can be accomplished with the help of radiant infrared heat, conduction or convection heat generation, or a combination thereof.

Infrared radiation is the most efficient heat transfer method used by industrial ovens. Meanwhile, of all the heat transfer methods used by industrial ovens, natural convection is the simplest. During convection, the force of gravity triggers fluid circulation, which triggers the rise of heated molecules and the fall of cool molecules. Convection is achieved through the transmission of heat from one object to another via gases and liquids. Common gases include natural gas and propane gas. Conduction is a less popular form of heat transfer in which heat is first transferred to air inside an oven, which is then applied to a solid object and then spread through the object. While methods other than these do exist, they are not very efficient and are less frequently used.

Safety and Compliance Standards

Because they work with heat, gas, etc., it’s very important that your industrial oven be up to code and safe. One of the main set of standards used for this in the INDIA are those put out by the NFPA (National Fire Protection Association). NFPA specifications outline ways for industrial oven manufacturers and consumers alike to avoid hazards during construction, installation and use.

To always be safe, we offer these tips:

- Always wear the sufficient protective gear. The right gear will keep you from directly inhaling gases and from have skin contact with hot parts or fire/gas/electrical parts.

- Make sure that your heating compartments are sealed, so that if there is a spill or something boils over, it won’t spread easily.

- Use ducts made from non-combustible materials.

- Regularly inspect ovens in accordance with safety standards and manufacturer recommendations.

- Regularly lubricate moving parts.

- Never leave oven unattended.