ABOUT NEEL INDUSTRIES

25 Long Years Of Manufacturing Excellence With Quality At It's Best!

Quality Comes First! We Make Sure That Every Minute Detail Is Looked Into While Manufacturing Even The Smallest Product. Our Focus Is 100% On Client Needs And Satisfaction.

Industrial ovens are thermal processing machines that provide various applications with the very important process of heat treatment. During this process, heat speeds up the molecular activity inside an object. Inside solid objects, molecules are arranged in lattices that vibrate from the heat, while in gases, these molecules collide. This activity changes the properties of the object it is heating, and strengthens it.

Our Industrial Products

We Offer Industrial Oven, Furnaces & Custom Built Allied Heating Systems.

Conveyor Oven

A conveyor oven is a continuous flow oven; it‘s an oven that is open on opposing sides and has a conveying system running from one end of the oven to the other. Designed like a batch oven, conveyor ovens have the additional benefit of keeping products moving while providing continuous and uniform heat.

MAX OPERATING TEMP: 1200 ºF

MAX WORKSPACE (WxDxH): 96" x 144" x 96"

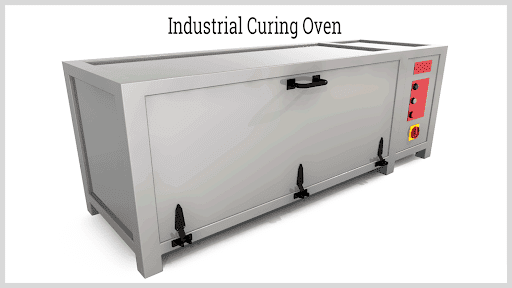

Curing Oven

curing oven is thermal processing equipment used by thermal specialists to improve or enhance the strength and durability of materials. Many factory processes such as baking, drying, heating, cooking, and curing require

MAX OPERATING TEMP: 1250 ºF

MAX WORKSPACE (WxDxH): 50" x 50" x 50"

Spiral Steam Oven

An industrial spiral steam oven is a device used to create extremely high temperatures to heat treat parts, condition metals, and cure metal coatings. Common functions for industrial ovens include drying, curing, testing, and coating of parts and products.

MAX OPERATING TEMP: 1200 ºF

MAX WORKSPACE (WxDxH): 96" x 144" x 96"

Overhead Conveyor Oven

Industrial ovens are thermal processing machines used as heating chambers for drying, curing, and baking of foods, parts, and components. The main industries that use industrial ovens are chemical and food processing

MAX OPERATING TEMP: 1250 ºF

MAX WORKSPACE (WxDxH): 50" x 50" x 50"

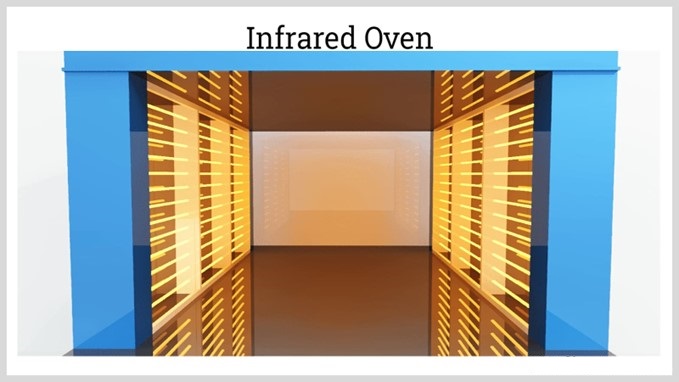

Infrared Oven

An infrared oven is an oven that heats objects or cooks food using infrared radiation instead of conventional conduction or convection heating. People can use infrared ovens in commercial kitchens, homes, or industrial settings.

MAX OPERATING TEMP: 1200 ºF

MAX WORKSPACE (WxDxH): 96" x 144" x 96"

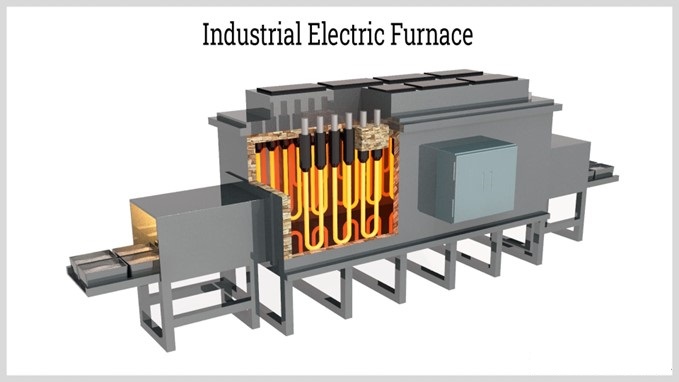

Furnace

A furnace is a piece of equipment that provides direct electric or fired heat for industrial processes that require temperatures that exceed 752 °F (400 °C). Furnaces are mostly used as a major component of a central heating system.

MAX OPERATING TEMP: 1250 ºF

MAX WORKSPACE (WxDxH): 50" x 50" x 50"

Laboratory Ovens

Low cost, fully equipped, all purpose laboratory ovens for sample drying, baking, annealing, conditioning, sterilizing, evaporating and dehydrating, and other general laboratory work.

MAX OPERATING TEMP: 518 ºF

MAX WORKSPACE (WxDxH): 18" x 12" x 16"

Furnaces

Used for a variety of heat treating applications such as tempering, hardening, sintering or firing, including those requiring inert atmospheres. Precision microprocessor based temperature controls and energy-saving insulation maximize the performance

MAX OPERATING TEMP: 1250 ºF

MAX WORKSPACE (WxDxH): 36" x 48" x 36"

Who We Are

We are the industry heads and produce the most reliable and trendy solution you are looking for.

We’ve created ovens and furnaces that work for every industry, every time.

No matter what your process is, our equipment just works. The first time, the 100th time, every time.

Trusted, dependable, long-lasting equipment for over 15+ years

Our ovens and furnaces run for decades with just preventative maintenance

Industrial Ovens and Furnaces That Fit All Your Requirements

Professional manufacturing and design

The only place where you’ll get the perfect solution for all your industry needs.

Our Contributions

Industries We Serve!

The word painting booth refers to paint and painting method. Painting without Painting Booth creates a bad and an unhealthy environment. Consistent quality, consistent production and eliminating rejection are key factors in todays competitive growing industry.

Humidity Ovens are designed for performing tests that need high humidity 90% to 95% RH at Ambient+10°C to 60°C temperature range; these equipment feature combination of laboratory oven with humidity system in one unit. At Neel industries, we have been manufacturing such humidity controlled ovens for over 40 years and these units are working efficiently throughout India in laboratories of reputed companies, Govt. institutions and research organizations.

Powder coating is a very specialty process when compared to painting process. Even if your production is less or more or very high , you need to have a complete system to carry out the powder coating process. In painting its quite easy to have a start up with a paint booth and eventually add more equipment for paint finishing improvement and new techniques